VuWall Technology Inc.

G&D and VuWall are proud to be part of the same corporate group.

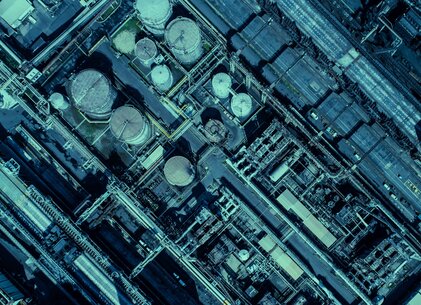

Discover VuWall's world-class video wall solutions, which work seamlessly with G&D's high-performance KVM systems to enable maximum flexibility, security, and efficiency in control rooms.

To the websiteDiscover VuWall's world-class video wall solutions, which work seamlessly with G&D's high-performance KVM systems to enable maximum flexibility, security, and efficiency in control rooms.